In the world of electronics and semiconductor manufacturing, having high-quality components is crucial. One of the most important components used in these processes is the test wafer. A test wafer acts like a blueprint that engineers use to ensure that their production methods and designs are accurate.

However, not just any wafer will do. Precision test wafer development is essential for reliable results. This type of development ensures that the wafers are created to exact specifications, allowing for effective testing and production.

What Is a Test Wafer?

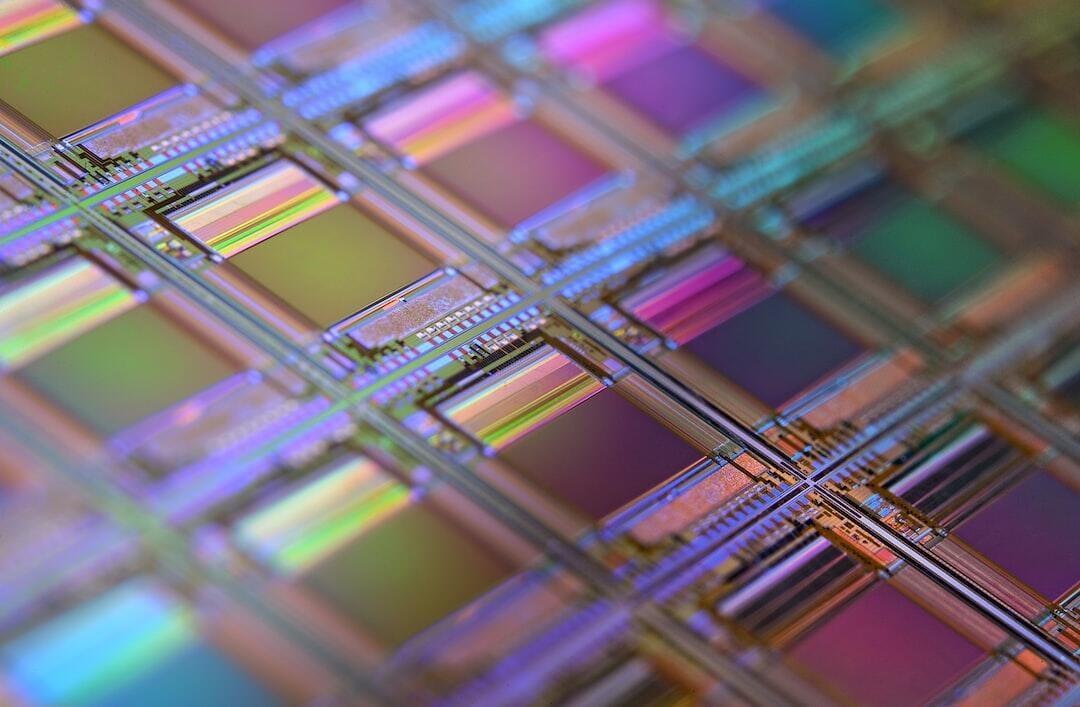

A test wafer is a thin slice of semiconductor material such as silicon. These wafers serve as the foundation for testing various electronic devices, ensuring that everything works smoothly before full-scale production begins.

Precision in the creation of these test wafers is critical. If the wafer is not made correctly, it can lead to flaws in electronics that can be costly to fix. Many manufacturers rely on patterned silicon wafers to ensure the accuracy of their designs, which is why having a stable supply of these wafers is so important.

Why Precision Matters

Precision in test wafer development is crucial for producing better products. The process of creating test wafers involves several intricate steps, and even a tiny mistake can have significant consequences. For example, if a test wafer has a minor defect, such as a misaligned pattern or a slight variation in thickness, it can result in defective chips.

These defective chips can then be used to manufacture a wide range of electronic devices, from smartphones to laptops, which may not function correctly. This can lead to unhappy customers, damage to a company’s reputation, and costly recalls. The recall of defective products can be extremely expensive, with some companies spending millions of dollars to replace or repair faulty devices.

By focusing on creating precise and high-quality wafers, manufacturers can significantly reduce the risk of errors and ensure that their devices work as intended. This attention to detail is similar to a master craftsman carefully assembling a complex machine, where every component must fit together perfectly to achieve optimal performance. In the same way, precise test wafers are the foundation upon which reliable a efficient electronic devices are built.

The Role of Continuity in Supply

Another crucial aspect of test wafer development is supply stability. Reliability in supply means that manufacturers always have the wafers they need when they need them.

Inconsistent supply can lead to project delays and can disrupt production schedules. To achieve continuity in supply, manufacturers often establish relationships with several suppliers, ensuring that they can always access the quality materials they require.

Building Strong Supplier Relationships

By working closely with multiple suppliers, manufacturers can create a safety net. If one supplier faces problems due to poor quality or late shipments, another supplier can step in. This practice not only helps maintain a steady flow of test wafers but also fosters competition between suppliers, which can lead to better pricing and quality.

Quality Control in Test Wafer Development

Quality control is vital in the development of test wafers. This procedure involves checking the test wafers at different production stages to ensure they meet specifications.

If any defects are found, manufacturers can address issues quickly, minimizing waste and ensuring only top-quality wafers are sent out for testing. Various methods are used in quality control, including visual inspections and advanced imaging techniques.

Advanced Techniques in Quality Assurance

Manufacturers are now using advanced technology like artificial intelligence (AI) to improve quality control. AI can detect subtle defects that are not visible to the human eye. This technology is like a pair of super powerful glasses that can see tiny problems.

Using AI in quality control is a big deal. It helps manufacturers make high-quality products that work well and last a long time. This is important for companies that want to build trust with their customers. When products are good quality, customers are happy and come back for more.

Some manufacturers are also using machine learning to improve quality control. Machine learning is a type of AI that can learn from experience. It’s like a robot that gets better at its job over time.

Overall, advanced technology like AI is changing the way manufacturers do quality control. It’s helping them make better products and build trust with their customers. This is a big step forward for companies that want to be the best.

Challenges in Test Wafer Development

Manufacturers face challenges in developing test wafers, even though precision, continuity, and quality are crucial. These challenges can come from several sources, like raw material shortages, equipment problems, and changing market demands. Understanding these challenges helps manufacturers prepare and set strategies to overcome them, ensuring consistent production.

Addressing Raw Material Shortages

One common challenge in the semiconductor industry is the shortage of raw materials such as silicon or other metals. To combat these shortages, companies are exploring new sources and alternatives for their materials.

Some manufacturers are investing in recycling programs. This helps recover and reuse materials. It stabilizes supply and is eco-friendly too.

The Future of Test Wafer Development

The future of test wafer development looks bright, with advancements in technology driving significant improvements in design and production methods. The electronics industry is growing fast. Manufacturers must adopt sustainable and efficient practices.

They should focus on precision and continuity. Also, they need to reduce the environmental impact of their production processes. This shift towards sustainability will be crucial in reducing the carbon footprint of test wafer development, making it a more environmentally friendly industry.

Embracing Innovation

Innovation will be the key driver of progress in the future of test wafer development. By embracing new techniques and technologies, such as 3D printing and nanotechnology, manufacturers can create even more precise and complex test wafers to meet the growing demands of the electronics industry.

For example, companies like Intel and Samsung are already investing in research and development of new materials and manufacturing processes, such as graphene and quantum dot technology, to improve the performance and efficiency of their test wafers.

The Importance of Precision, Supply Stability, and Quality

In summary, the combined aspects of precision, continuity of supply, and rigorous quality control form the backbone of effective test wafer development. By focusing on these areas, manufacturers can produce reliable test wafers.

These wafers are not just vital for testing electronic devices; they symbolize the craftsmanship and care that goes into creating quality products. A commitment to excellence in test wafer production will ensure a brighter, more innovative future in electronics.

For more helpful tips, check out the rest of our site today.