The electronic manufacturing process is the backbone of every modern electronic device, from smartphones and medical equipment to automotive controllers and industrial automation systems. It is a structured sequence of steps that transforms a circuit idea into a fully functional electronic product. Understanding this process is essential for engineers, OEMs, startups, and businesses that aim to develop reliable, high-performance electronics. A well-optimized electronic manufacturing process not only improves quality but also reduces production time, cost, and risk.

Understanding the Electronic Manufacturing Process

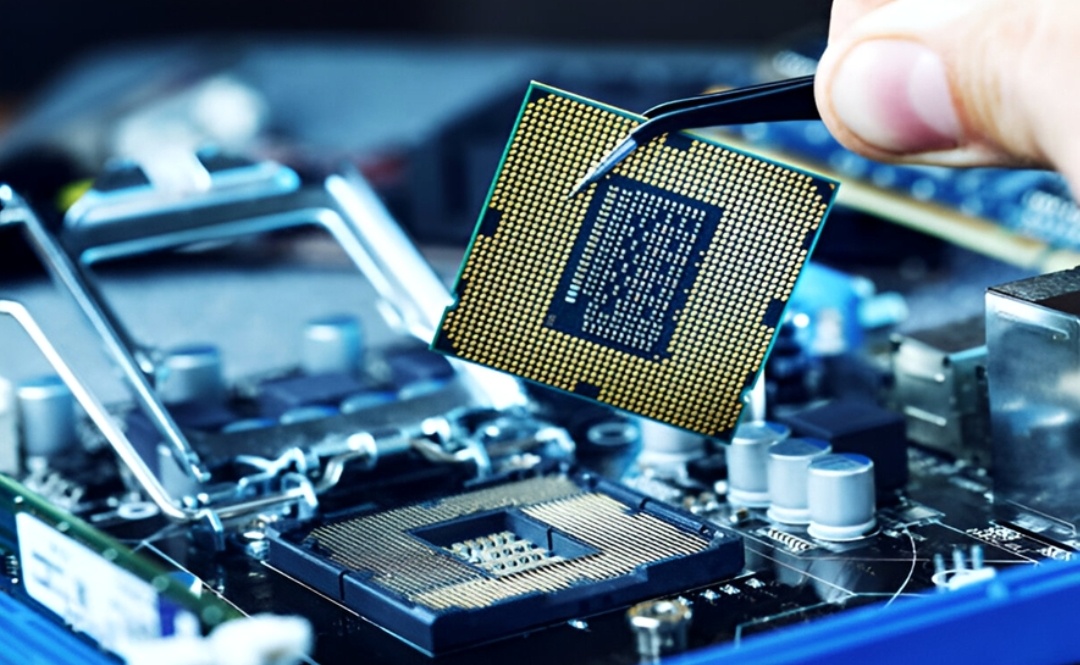

The electronic manufacturing process refers to the complete journey of an electronic product—from circuit design and PCB development to component sourcing, assembly, testing, and final packaging. Each stage must be executed with strict precision because even a small deviation can lead to malfunction, defects, or failures in the field. Today’s electronics use miniaturized components, fast processors, and high-density PCBs, which makes strict quality control more important than ever.

Modern electronics manufacturing integrates advanced assembly technologies such as SMT, automated optical inspection (AOI), reflow soldering, X-ray verification, and functional testing. These steps ensure that every product meets industry standards and performs reliably in real-world applications.

1. Circuit Design and Prototyping

The electronic manufacturing process begins with circuit design, including schematic creation, component selection, and simulation. Engineers analyze current flow, signal behavior, heat dissipation, and EMI/EMC performance. Once the design is complete, it transitions to PCB layout, where layers, pads, traces, and vias are optimized according to the functional and mechanical requirements.

After PCB layout, manufacturers create prototype boards to validate the design. Prototyping helps engineers identify potential issues early, such as component misplacement, insufficient spacing, or signal interference. Once the prototype works perfectly, the design moves into mass production.

2. PCB Fabrication

Printed Circuit Board fabrication is one of the most important stages in the electronic manufacturing process. Here, the physical PCB is created using layers of copper, fiberglass, or advanced materials like Rogers, PTFE, or polyimide. PCB fabrication involves:

- Photo-imaging

- Copper etching

- Drilling and via formation

- Plating

- Lamination

- Surface finishing

Common finishes include ENIG, HASL, OSP, immersion silver, and hard gold. The quality of PCB fabrication directly affects electrical performance, thermal stability, and product durability.

3. Component Sourcing and BOM Management

Next comes component sourcing, where every part listed in the Bill of Materials (BOM) must be purchased from reliable suppliers. Manufacturers check:

- Availability

- Authenticity

- Price

- Lead time

- Lifecycle (to avoid obsolete components)

This stage is crucial because counterfeit or low-quality components can cause system failure, short circuits, or performance issues. Experienced manufacturers use authorized distributors and certified vendors to ensure 100% original parts.

4. SMT Assembly (Surface-Mount Technology)

SMT assembly is at the heart of the electronic manufacturing process. Most modern electronics use surface-mount components due to their small size and high performance. SMT assembly includes:

- Solder paste printing on PCB pads

- Pick-and-place of tiny electronic components

- Reflow soldering inside temperature-controlled ovens

- AOI inspection to detect solder defects or misalignment

High-density electronics like mobile phones, wearables, and IoT devices rely heavily on advanced SMT technology.

5. Through-Hole Assembly

Some components, such as connectors, large capacitors, and transformers, require through-hole assembly. These components are mounted manually or using automated insertion machines. Wave soldering or selective soldering is used to strengthen these joints, especially for products requiring high mechanical stability.

6. Inspection and Quality Control

Every high-quality electronic manufacturing process includes multiple inspection and testing stages:

- AOI (Automated Optical Inspection) to check solder joints

- SPI (Solder Paste Inspection) to verify paste volume and placement

- X-ray inspection for BGA, QFN, and hidden-lead components

- ICT (In-Circuit Testing) for electrical validation

- Functional testing to ensure the product performs its intended tasks

Manufacturers use strict IPC-A-610 and ISO quality standards to verify reliability.

7. Final Assembly and Packaging

After PCB assembly and testing, products move to final assembly, where housings, connectors, wiring, and mechanical parts are integrated. Once assembled, electronic devices undergo:

- Burn-in tests

- Environmental stress tests

- Aging tests

- Final inspection

Finally, the product is cleaned, packed, labeled, and prepared for shipping.

Why the Electronic Manufacturing Process Matters

A smooth and optimized electronic manufacturing process ensures:

- High product reliability

- Faster time-to-market

- Lower production cost

- Competitive quality standards

- Stronger long-term brand value

Businesses that rely on electronics—whether industrial, automotive, consumer, or medical—need a manufacturing partner who understands precision engineering, quality control, and advanced assembly technologies.

Conclusion: Get Reliable Electronic Manufacturing Support

If you want your product to perform flawlessly, choosing the right manufacturing partner is essential. A professional PCB Fabrication & Assembly Company can handle every stage of the electronic manufacturing process—from design and prototyping to SMT, testing, and final assembly—ensuring consistent quality and on-time delivery for every project.