Look, if you’re designing products in 2026, you already know the pressure. Faster iterations. Tighter budgets. Quality that can’t slip. Here’s what expert 3D printing services actually solve for you: getting production-ready prototypes in your hands without dropping cash on equipment or spending months learning materials science

When you team up with professional 3D printing partners, you tap into 3D printing services that collapse what used to take months into mere days. This guide breaks down how 3D printing for product designers gives you the speed, technical flexibility, and cost efficiency that keeping everything in-house just can’t deliver.

Benefits of 3D Printing for Product Designers Across Design Phases

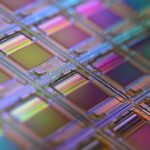

Additive manufacturing isn’t simply faster prototyping. It’s fundamentally a different design vocabulary that opens up geometry and workflows traditional manufacturing just can’t handle.

Complex geometry freedom that traditional methods can’t match

Topology-optimized brackets, internal cooling channels, lattice structures—none of these need special tooling anymore. The benefits of 3D printing become obvious the moment you need snap-fit assemblies, living hinges, or integrated fastener bosses that would be nightmarish to mold.

Sacramento’s design scene has matured alongside regional manufacturing clusters, with more teams seeking partners who genuinely understand both digital workflows and hands-on collaboration. When you’re running iteration-heavy projects where rapid local turnaround actually matters, 3d printing Sacramento services can compress timelines through same-day pickups and face-to-face design consultations.

Design freedom also means part consolidation. Five molded components plus assembly labor? That can become one integrated print with zero fasteners.

Engineering validation with repeatable results

Consistency matters when you’re running tests. Professional services log batch numbers, print orientation, process parameters—everything that makes repeat builds trustworthy. Set your acceptance criteria upfront: flatness tolerances, hole position accuracy, minimum wall thickness thresholds.

Gauge R&R thinking applies to prototypes too. When three prints from identical files show dimensional drift, you’ve got a process issue, not a design flaw.Matching the right technology to each milestone? That’s where efficiency lives. Here’s how to align printing processes with your actual design requirements.

Product Design Wins With Professional 3D Printing Services

Here’s the thing—speed and precision aren’t luxury features anymore. They’re what keep you competitive. Professional partners hand you both without the headache of babysitting machines.

Prototype cycles that shrink from weeks to days

The iteration game? Completely transformed. Complex parts now print in windows that would’ve seemed impossible five years ago. Some retail applications already crank out complete garments in roughly 90 minutes. Sure, not everything prints that quickly, but the fundamental shift is real: professional services convert your CAD files into tangible parts within days instead of dragging on for weeks.

Sprint-based workflows suddenly make sense. Day zero you lock down CAD. Day one the part’s printing. Day two you’re testing fit and function. Day three you’re already revising. That rhythm gives you four complete design cycles monthly instead of one painful iteration.

Early-stage risk reduction with functional validation

“Looks right” and “works right” are worlds apart. Fit-check prototypes confirm your assembly clearances actually work. Functional testing validates mechanical loads, how heat affects things, and wear patterns under real conditions. Pre-production pilots surface manufacturing headaches before you’ve committed to expensive tooling.

Build yourself a test matrix: load testing, heat exposure, UV stability, chemical resistance, drop tests, fatigue cycles. Document everything—what passed, what failed. That data becomes your roadmap for revision two.

Understanding *when* Does additive make strategic sense? That separates designers who get by from designers who consistently ship great products. Let’s dig into how these advantages multiply across every stage.

Process Selection Guide for 3D Printing for Product Designers

Different technologies serve wildly different purposes. Pick wrong and you’re burning time and budget.

FDM for quick fit checks and large concepts

Fused deposition shines for early-stage size verification and assembly validation. It’s quick and economical. Realistic tolerances run around ±0.3mm on decent equipment. Expect visible layer lines and anisotropic strength—parts are substantially weaker perpendicular to build layers.

Design tips: maintain walls above 1.2mm, watch those overhangs past 45 degrees, and add chamfers at stress concentration points to compensate for directional strength characteristics.

SLS/MJF for durable functional parts

Selective laser sintering and Multi Jet Fusion produce tough, isotropic parts without requiring support structures. They’re perfect for snap fits, living hinges, and intricate assemblies. Surface finish comes out grainy but predictably consistent.

Design for powder escape—any enclosed cavity needs drain holes. Parts nest efficiently inside the build chamber, which dramatically reduces per-unit costs on smaller production runs.Even perfect process selection fails without intelligent material choices. Let’s map your requirements to polymers that actually perform.

Cost Control With Expert 3D Printing Services

Budget constraints and timeline pressures? Absolutely real. Smart designers know exactly which levers to pull without compromising performance.

Pricing drivers you can influence

Part volume, build height, infill density, support structures, post-processing—all impact final cost. Hollowing parts while adding internal ribbing maintains structural integrity while slashing material consumption. Self-supporting angles (staying under 45 degrees from vertical) eliminate support waste entirely.

The North American 3D printing market hit USD 4.46 billion in 2022 and is projected to reach USD 16.59 billion by 2032, growing at 15.7% annually. This expansion drives more competition, better pricing structures, and specialized vendors who actually understand designer requirements.

Split oversized parts into smaller assemblies when it makes strategic sense. You’ll cut print time, boost yield rates, and simplify reprints when one section needs tweaking.

ROI vs in-house printers

Buying equipment seems tempting until you actually calculate hidden costs. Failed prints waste both material and time. Machines demand calibration, ongoing maintenance, and part-time operator attention. You’ll inventory multiple materials (each with finite shelf life), troubleshoot adhesion problems, and manage ventilation requirements for certain polymers.

Professional services spread those operational costs across hundreds of clients. You’re paying for successful parts delivered, not the learning curve.Demonstrated capability and communication quality separate true experts from simple button-pushers. Use these criteria when evaluating potential partners.

Choosing the Right Partner for Professional 3D Printing

Not all service providers create equal value. You want partners who actively improve your designs, not just print whatever file you upload.

Quality systems and proactive feedback

Ask about dimensional inspection capabilities, material certifications, batch consistency tracking protocols. The strongest vendors flag design risks before hitting print: thin walls, unsupported features, tolerance conflicts that’ll cause problems.

Request first-article inspection documentation on critical parts. That paperwork proves the process capability before you commit to larger runs.

Local collaboration advantages

Regional partners deliver benefits purely online services simply cannot. Faster pickup times compress iteration loops significantly. In-person design reviews catch issues CAD review alone might miss. Quick turnaround on revised parts maintains momentum when timelines get aggressive.

Before we wrap, let’s address the practical questions most articles conveniently skip.

Questions Designers Ask About Professional 3D Printing

1.Which process gives the tightest tolerances for assemblies?

SLA resin printing typically achieves ±0.1mm accuracy on small features, making it ideal for tight-fitting mechanical assemblies and threaded connections. SLS and MJF follow closely with ±0.3mm for functional components.

2.How do snap fits work reliably with 3D printing?

Design snap features perpendicular to build layers when using FDM to maximize strength characteristics. SLS and MJF handle snap geometry more reliably due to isotropic properties. Test deflection limits with sample coupons before finalizing your geometry.

3.Can printed parts replace injection molding for end-use products?

Absolutely, when annual volumes stay below 5,000–10,000 units or when design changes happen frequently. High-performance nylons from SLS/MJF offer durability genuinely comparable to molded parts for many applications.

Making the Most of Expert Printing Services

Product designers don’t need to transform into manufacturing experts to consistently deliver exceptional work.

Partnering with expert 3D printing services hands you immediate access to technology platforms, materials expertise, and quality systems that would require years to develop in-house. The speed advantage alone—moving from CAD to physical validation within days—compresses development timelines enough to justify the partnership cost.

Layer in eliminated capital investment, zero maintenance headaches, and professional-grade finishing options, and the value proposition becomes crystal clear. Choose partners who communicate proactively, track quality rigorously, and treat your timeline with the same urgency you do.